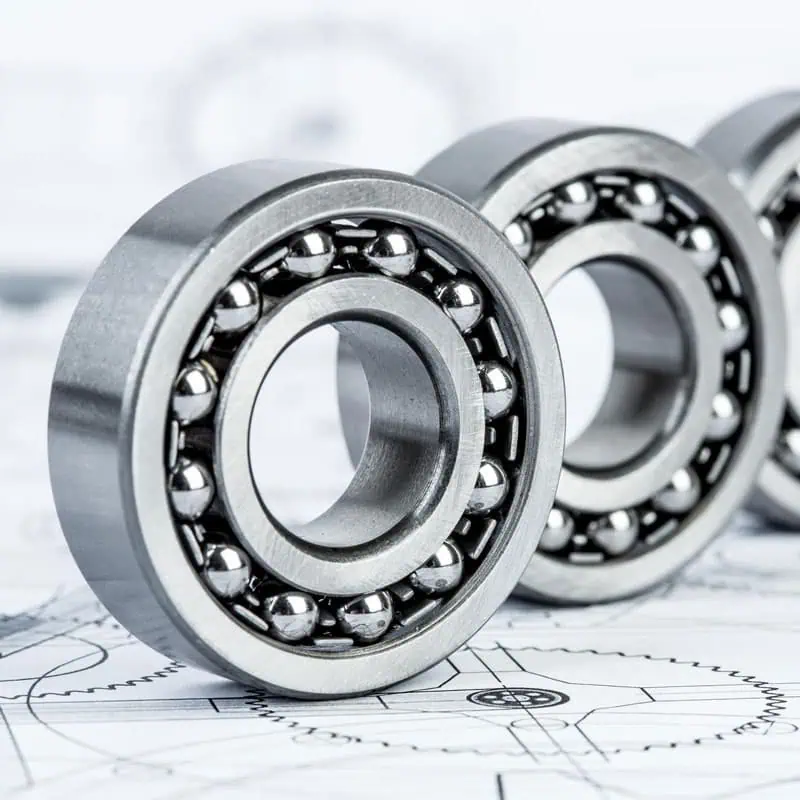

Choosing the right bearings for your industry is a critical decision that directly impacts the efficiency, reliability, and lifespan of your machinery. With countless options available, it’s essential to understand how to select bearings that meet your specific operational requirements. At Kinex Bearings, we specialize in providing high-quality solutions tailored to diverse industries. Here, we share insights to help you make informed decisions when selecting the right bearings for your applications.

Understand Your Application Requirements

The first step in selecting the right bearings is to fully understand the operational requirements of your machinery. Key considerations include:

- Load Types: Determine whether the load is radial, axial, or a combination of both. For example, ball bearings are ideal for light to moderate radial loads, while tapered roller bearings are better suited for handling combined loads.

- Speed Requirements: Consider the operating speed of your machinery. High-speed applications often require precision bearings with minimal friction, such as angular contact ball bearings or hybrid ceramic bearings.

- Environmental Conditions: Identify the working environment. Bearings used in harsh conditions—such as high temperatures, moisture, or contamination—may require special coatings, seals, or materials.

- Size and Space Constraints: Ensure the bearing fits within the available design envelope of your machinery without compromising performance.

Choose the Right Bearing Type

Different bearing types offer unique advantages depending on the application. Below are common bearing types and their typical uses:

- Deep Groove Ball Bearings: Ideal for versatile applications requiring high rotational speeds and moderate loads. Commonly used in electric motors, pumps, and fans.

- Spherical Roller Bearings: Designed for heavy loads and misalignment. Perfect for industries like mining, steel, and paper production.

- Tapered Roller Bearings: Best for handling combined axial and radial loads. Widely used in automotive and gearbox applications.

- Needle Roller Bearings: Excellent for applications with space constraints and high load capacity requirements, such as automotive transmissions and compressors.

- Thrust Bearings: Specially designed for axial load applications like turbines and cranes.

Consider Material and Coating Options

The material and coating of a bearing can significantly influence its performance and durability. Options include:

- Steel Bearings: Standard choice for most applications due to their strength and durability.

- Ceramic Bearings: Suitable for high-speed and high-temperature environments, offering reduced friction and extended lifespan.

- Coated Bearings: Protective coatings such as anti-corrosion or anti-wear layers enhance performance in harsh conditions.

Kinex Bearings offers a wide range of materials and coatings to meet the unique demands of your industry.

Focus on Precision and Tolerances

Precision is critical in high-performance applications, such as aerospace and medical technology. Bearings with tighter tolerances and higher precision ratings ensure smoother operation, reduced noise, and longer service life. Be sure to select bearings that align with the precision requirements of your equipment.

Evaluate Lubrication Needs

Proper lubrication is essential to reduce friction and prevent premature wear. Consider the following:

- Grease-Lubricated Bearings: Ideal for general applications with moderate speeds and loads.

- Oil-Lubricated Bearings: Recommended for high-speed or high-temperature environments.

Kinex Bearings provides guidance on selecting the right lubrication and even offers pre-lubricated bearing options for convenience.

Partner with a Trusted Bearing Supplier

Working with a reliable bearing manufacturer is key to ensuring the quality and performance of your bearings. Kinex Bearings has decades of experience serving industries such as automotive, railway, and energy. We pride ourselves on delivering innovative, durable, and customized solutions that meet the highest standards of quality.

Conclusion

Choosing the right bearings for your industry doesn’t have to be overwhelming. By understanding your application requirements, selecting the appropriate bearing type, and focusing on material, precision, and lubrication, you can ensure optimal performance and reliability for your machinery. With Kinex Bearings as your trusted partner, you’ll gain access to world-class bearing solutions designed to meet the unique challenges of your industry.

Ready to find the perfect bearing for your application? Contact Kinex Bearings today to learn more about our wide range of products and expert solutions.