In today’s high-performance industrial environments, every component is important and when it comes to minimizing friction, reducing wear, increasing operating efficiency and special bearing housings, ceramic bearings can be used. Known for their precision, longevity, lightweight properties, high thermal stability and electrical insulation, ceramic bearings are redefining expectations in various industrial applications.

From electric vehicles and aerospace to high-speed machining and medical devices, ceramic bearings are engineered to deliver reliable performance in the most demanding conditions. This article explores what makes ceramic bearings a superior choice and highlights their growing use in traction motor systems.

What Are Ceramic Bearings?

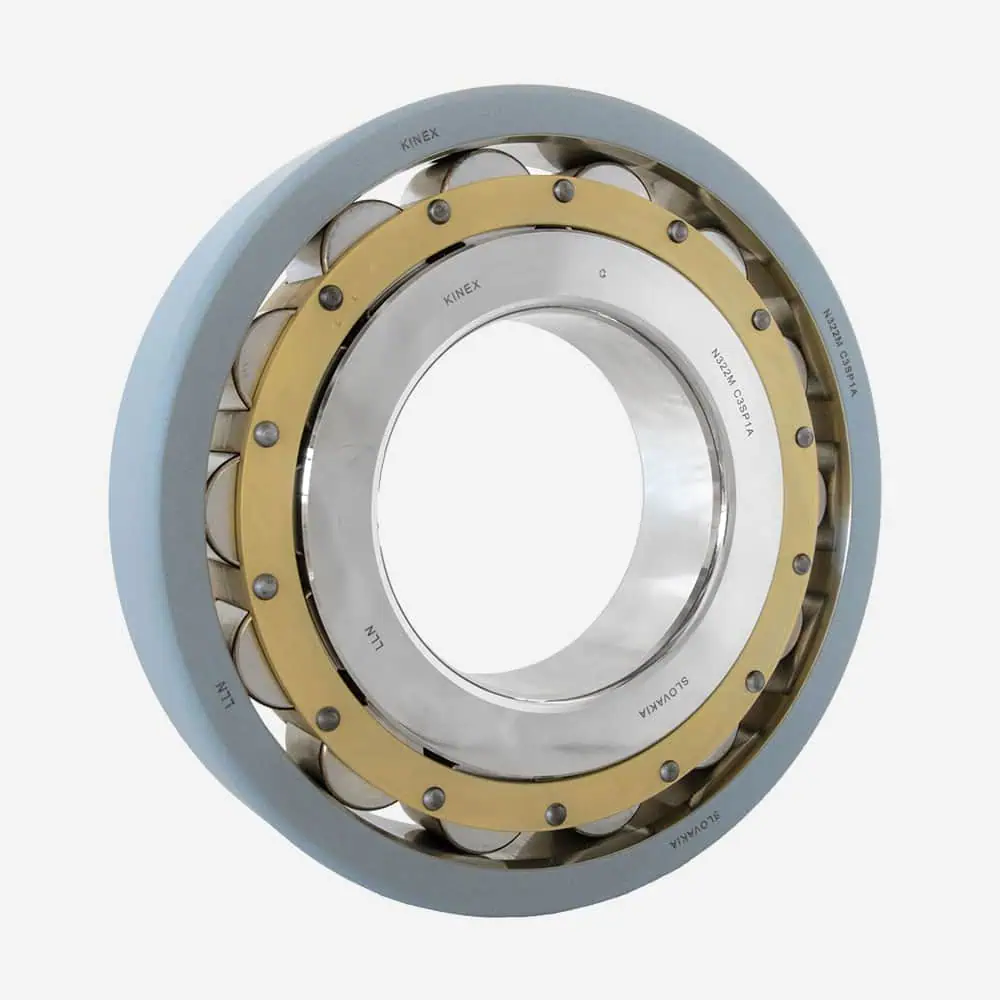

Ceramic bearings use rolling elements made from advanced ceramic materials such as silicon nitride (Si₃N₄) or zirconia (ZrO₂), instead of traditional steel. They are often hybrid, combining ceramic balls with stainless steel or steel raceways, or coating the inner and outer diameters. Pure ceramic bearings also exist for specialized applications.

Key Advantages of Ceramic Bearings:

- High precision and roundness: Ceramic balls are manufactured to extremely tight tolerances, allowing for smoother and more accurate rotation.

- Low friction: Less friction means lower operating temperatures, better energy efficiency, and less lubricant requirement.

- High-speed capability: Ideal for high-RPM environments due to reduced centrifugal force and heat generation.

- Corrosion resistance: Ceramic materials are non-reactive and do not corrode in moist or chemically aggressive environments.

- Non-conductive properties: A critical benefit in electric motor applications, preventing electrical arcing through the bearing.

Ceramic Bearings for Traction Motors

As electric mobility and rail transport evolve, traction motors especially those used in electric trains and high-speed rail demand components that can perform under constant stress, high speeds, and variable load conditions. Ceramic bearings meet these needs with high efficiency.

Benefits in Traction Motor Applications:

- Electrical insulation: Prevents current leakage and bearing damage due to voltage build-up in the shafts of electric motors.

- Extended service life: Lower wear and higher hardness lead to longer intervals between maintenance and replacements.

- Reduced noise and vibration: Enhances passenger comfort and system stability in electric rail vehicles.

- High thermal stability: Operates reliably in varying temperature environments often encountered in rail and transit systems.

Ceramic bearings also contribute to energy savings and lower overall consumption costs, which is especially important in long-term transport fleet operations.

Applications Across Industries

Ceramic bearings are not limited to traction motors. Their versatility and performance benefits make them ideal for a wide range of industries:

- Aerospace: Lightweight and thermally stable components improve fuel efficiency and reliability.

- Medical: Non-magnetic and biocompatible bearings are used in MRI-compatible equipment and surgical tools.

- Machine tools: High-precision bearings enable faster cutting speeds and greater tool life.

- Semiconductor manufacturing: Particle-free, cleanroom-grade bearings support ultra-clean environments.

Choosing the Right Ceramic Bearings

When selecting ceramic bearings for your application, consider the following:

- Material type (silicon nitride vs. zirconia)

- Hybrid vs. full ceramic

- Load capacity and operating speed

- Environmental factors (e.g., temperature, chemicals, moisture)

- Electrical requirements (insulating properties)

Working with a trusted bearing supplier like KINEX BEARINGS ensures you get the right configuration and performance specifications for your industry’s challenges.

Conclusion

Ceramic bearings are transforming industrial systems with their unmatched precision, durability, and performance. As industries demand more speed, efficiency, and reliability, these advanced bearings offer a compelling solution especially in electrified applications like traction motors. By integrating ceramic bearing technology, companies gain a competitive edge through enhanced system performance, reduced downtime, and long-term value.

Looking to upgrade to high-performance ceramic bearings? Contact KINEX BEARINGS to find the perfect solution for your needs.