The correct bearing lubrication has a direct influence on the bearing life. Lubricant creates between the rolling element and bearing ring a carrying lubricating film which hinders their metal contact. It lubricates surfaces where friction arises, it has cooling effect, it protects the bearing from corrosion and in many cases seals the bearing space.

In the most cases – approximately 90%, bearings are lubricated with grease or oil, in rare exceptions by other lubricating means. When deciding which lubricant and which lubrication type should be used, operating conditions, characteristic qualities of the lubricant, equipment design and operating economy should be taken into account.

Grease Lubrication

In the design practice grease lubrication is preferred to oil lubrication from the point of view of arrangement simplicity, utilization of the sealing capabilities and simple maintenance.

For reliable bearing operation 1/3 to 1/2 of its free space is filled with grease at the first assembly. A greater grease amount has negative influence on the operation. Higher passive resistances cause the inner bearing space warming up undesirabely, which can lead to its breakdown. Bearings making only a small number of revolutions during operation, from the point of view of corrosion protection should be completely filled.

Relubrication Interval

Relubrication interval is the period during which the grease has the necessary lubricating properties. After this period bearing must be relubricated, and old lubricant must be removed from the bearing space completely.

Relubricating period depends on the bearing type and size, rotational speed, operating temperature and grease quality. The recommended relubrication period for individual bearing types at normal load (P ≤ 0.15 C) and normal operational conditions is shown in diagrams in Pict. 1 and 2. The diagrams are valid for common greases and temperatures to +70°C. For temperatures over +70°C, the relubrication period is shortened for each 15°C on the half of original value. For temperatures under +40°C the relubri ca tion period can be doubled.

For small sized, especially single row ball bearings, the relubrication periods are several times longer than the bearing life, that is why the bearings are, as a rule, not relubricated. For this reason it is advantageous to use these bearings shielded or sealed on both sides and filled with grease. For some rotational speeds the relubrication period is out of the diagram curve, i.e. the permis sible limit for grease lubrication has been reached and oil lubrication should be used.

Necessary grease quantity for relubri cation is calculated from the equation:

Q = 0.005 DB

Q – grease quantity [g]

D – bearing outer diameter [mm]

B – bearing width [mm]

For bearings with higher rotational speed requiring a more frequent relubrication, it is necessary to remove the used lubrication from the bearing space so that temperature increase should not occur. For this reason the grease escape valve is suitable.

Bearing Greases

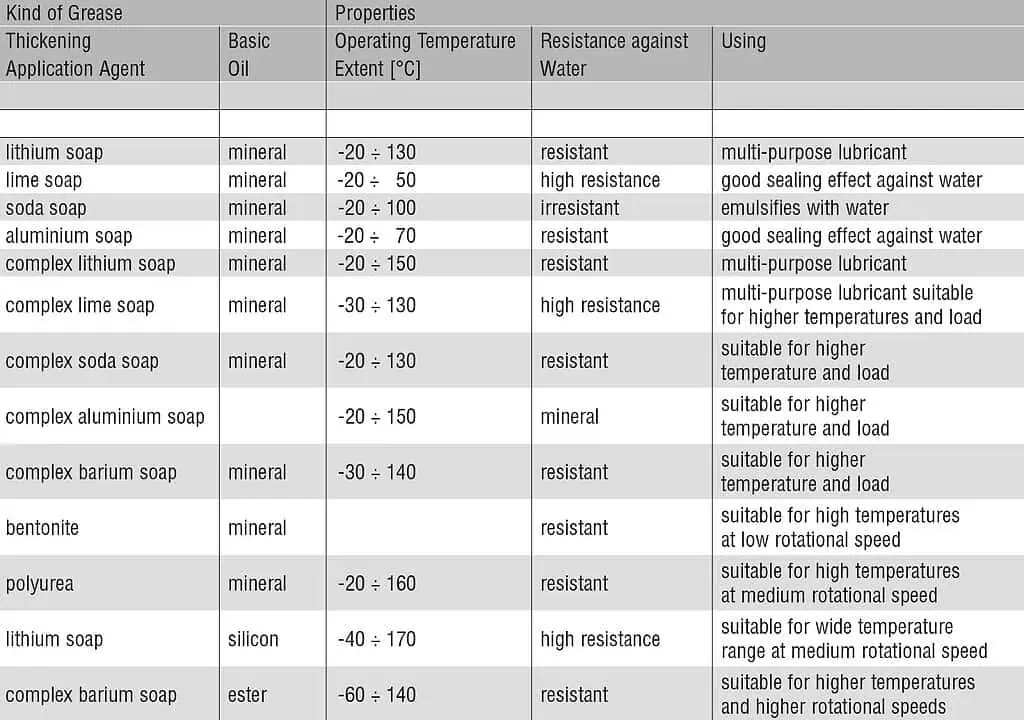

Bearing greases are produced most often of quality mineral or synthetic oils (sometimes with additives), thickened with fatty acid metallic soaps. Greases must have good lubricating properties and high chemical, temperature and mechanical stability. The grease list of bearing lubricants is in Table 1.

Rolling Bearing Grease Properties

Oil Lubrication

Oil lubrication is used, when operating rotational speed is so high that the grease relubrication period is too short. Another reason can also be the necessity of heat transfer from the bearing, or the high temperature of environment, which does not enable utilization of grease, or if surrounding parts are already lubricated by oil (e.g. geared wheels in the gear box). Except for some cases, spherical roller thrust bearings are always lubricated by oil. When oil lubricating, lubricating must be secured both at starting and during operation. Excess oil increases tempera ture and bearing temperature. Oil feed into bearing is secured in various design ways, out of which oil bath lubrication with oil level reaching middle of the lowest rolling element, oil circulation lubrication, jet lubrication, oil mist lubri cation etc., are the most common.

Bearing Oils

For bearing lubrication mostly refined oils with good chemical stability which can be improved by antioxidizing agents are used. The decisive oil property is kinematic viscosity which decreases with increasing temperature. Suitable oil viscosity υ1 can be stated according to the diagram in Pict. 2 in dependence on the bearing mean diameter ds = (d+D)/2 and rotational speed n. If the operating temperature is known or it can be found out, according to the diagram in Pict. 3 suitable oil and viscosity υ at internationally standardized temperature 40°C being necessary for calculation of ratio χ is determined. By ratio χ < 1 it is recommended to use EP oil with additives which improve the oil film load rating. By value χ decrease under 0.4 oils with EP additives are always used.

If the ratio χ is greater than 1, improved arrangement reliability is reached in operation.

Example:

- bearing d = 180 mm, D = 320 mm, ds = 250 mm

- rotational speed n = 500 min-1

- presumed operating temperature 60°C

For these conditions according to diagram in Pict. 3 the minimum kinematic viscosity is υ1 = 17 mm2 .s-1.

If the operating temperature is 60°C, the oil selected according to the diagram in Pict. 4 at standardized temperature 40°C must have kinematic viscosity υ min. 35 mm2.s-1.

Lubrication with Solid Lubricants

Solid lubricants are used for bearing lubrication when the grease or oil cannot fulfil the requirements for reliable lubrica tion in conditions of limiting friction or from the viewpoint of high operating tempe ratures, chemical influences, etc.

Conclusion

Proper bearing lubrication is an investment in performance and durability. By applying the right lubricant in the right amount, engineers can significantly increase bearing lifespan, reduce maintenance costs, and optimize efficiency in every industrial application. Contact us for more information.