Understanding Bearing Failure

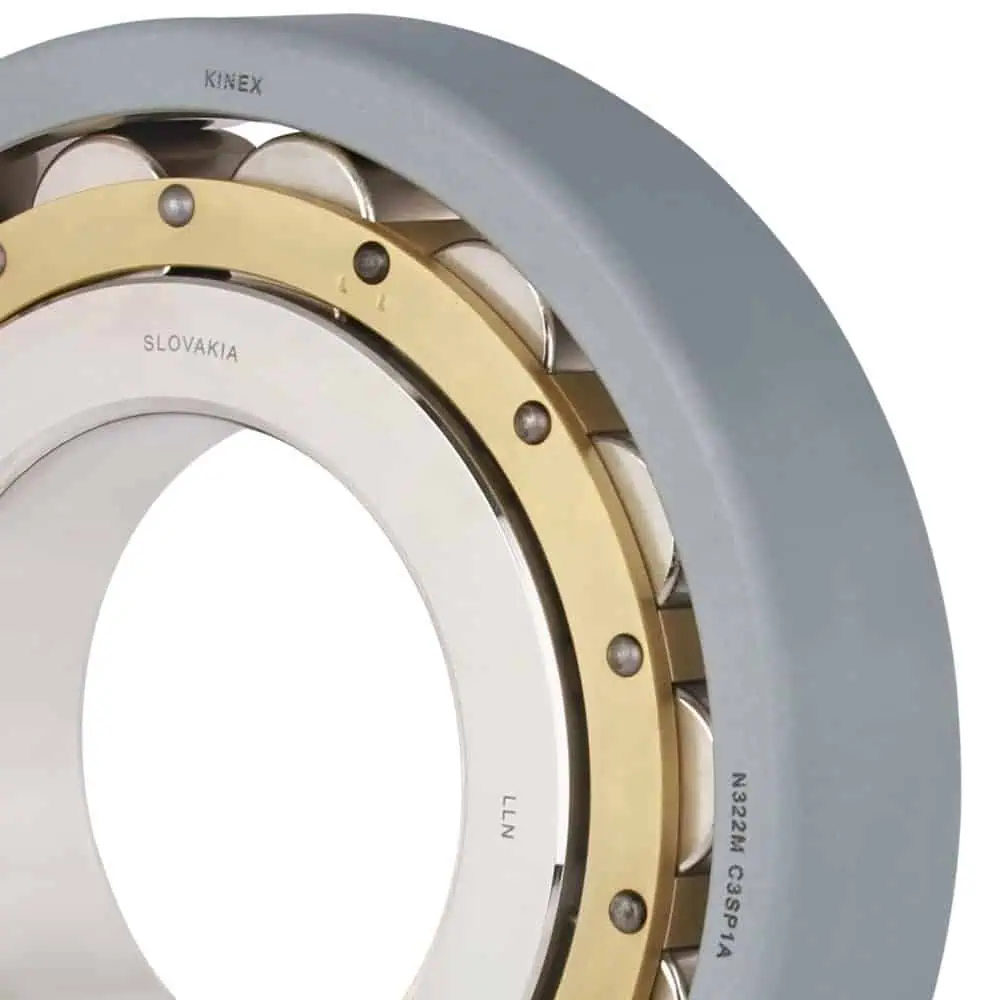

Bearings are among the most critical components of most machines and must meet high requirements for load capacity and reliability.

Bearing failure is one of the most common causes of unplanned machine downtime. Even a minor defect can escalate into a serious mechanical problem, leading to equipment damage, production stoppages, and high maintenance costs. The causes can vary higher-than-expected loads, insufficient or inappropriate lubrication, improper handling, ineffective sealing, or mounting with excessive interference resulting in insufficient internal bearing clearance. Each of these factors causes a specific type of damage and leaves characteristic marks on the bearing.

Main Causes of Bearing Failure

Each individual cause of bearing damage leaves characteristic traces. From these damages, referred to as primary damages, secondary damages develop, which ultimately lead to failure such as flaking and cracking. Primary damages alone may also require bearing replacement due to excessive internal clearance, increased vibration, noise, or similar issues. A failed bearing often exhibits a combination of both primary and secondary damages.

Insufficient or Incorrect Lubrication

Over 50% of bearing failures are linked to lubrication problems. Too little lubrication increases friction and temperature, while excessive or incompatible lubricant leads to instability and shortened bearing life.

Contamination and Foreign Particles

Dust, metal particles, moisture, and chemicals can enter the bearing, damaging raceways and rolling elements. Contamination is especially problematic in harsh industrial environments.

Misalignment and Improper Mounting

Incorrect installation puts additional stress on the bearing. Misalignment between the shaft and housing results in uneven load distribution and accelerated wear.

Overloading and Shock Loads

Bearings are designed for specific load ranges. Excessive radial or axial forces, as well as sudden impacts, can deform rolling elements and reduce bearing reliability.

High Temperatures

Elevated operating temperatures change material hardness and degrade lubricants, increasing the risk of premature failure.

Symptoms of Bearing Failure

Increased Noise or Vibration

Unusual sounds or sudden vibration spikes often indicate internal damage such as pitting, spalling, or lack of lubrication.

Excessive Heat

A rapid temperature rise is an early warning sign of friction, contamination, or incorrect mounting.

Reduced Performance or Efficiency

Machines may require more power to operate, or rotating parts may feel less smooth when turned manually.

Visible Wear or Corrosion

Surface damage, rust marks, and color changes indicate that the bearing is close to failure.

How to Prevent Bearing Failure

Use Proper Lubrication Practices

Choosing the right lubricant, monitoring intervals, and using automated lubrication systems significantly extend bearing life.

Keep Bearings Clean and Protected

Seals, shields, and correct storage prevent contamination and moisture ingress

Ensure Correct Mounting and Alignment

Following manufacturer guidelines reduces unnecessary stresses during operation.

Monitor Loads and Operating Conditions

Sensors and predictive maintenance systems help detect overloads or temperature changes early.

Select the Right Bearing for the Application

Choosing bearings with suitable materials, clearances, and load ratings ensures long-term reliability.

Conclusion

Bearing failure is preventable when proper lubrication, installation, and monitoring practices are in place. With high-quality engineering and precise manufacturing, KINEX bearings are designed to operate reliably under challenging industrial conditions.

FAQ

A thorough inspection of the damaged bearing therefore makes it possible, in most cases, to identify the cause of the damage and to implement measures that prevent its recurrence.

1. What is the most common cause of bearing failure?

The majority of bearing failures are caused by lubrication issues—either too little lubrication, contaminated grease, or the wrong type of lubricant for the application.

2. What are early signs of bearing failure?

Increased noise, vibration, temperature spikes, and reduced operating smoothness are the most common early warning signs.

3. How can bearing failure be prevented?

Proper lubrication, correct mounting, clean operating conditions, and regular monitoring of load and temperature significantly reduce the risk of failure.

4. How does contamination affect bearings?

Dust, metal particles, and moisture damage the raceways and rolling elements, leading to accelerated wear and premature bearing failure.

5. When should a bearing be replaced?

If you notice unusual noise, rising temperature, vibration changes, or visible surface damage, replacing the bearing is recommended before it causes additional equipment damage.