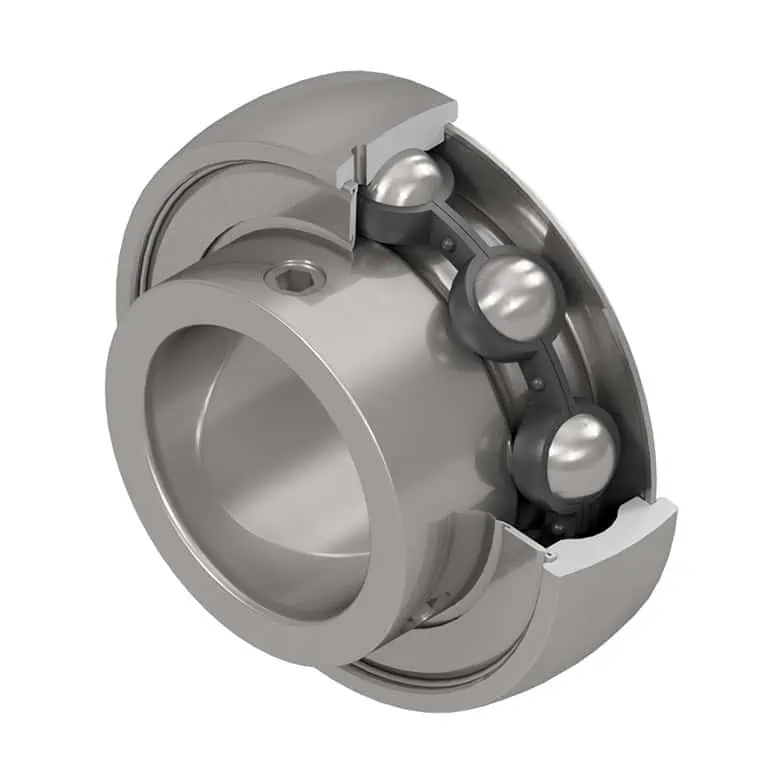

Spannlager US200

Klemmlager sind für die Lagerung kurzer Wellen und für Lagerungen geeignet, bei denen geringe Wärmeausdehnungen auftreten, die durch das axiale Spiel in den Lagern oder durch die Nachgiebigkeit der Konstruktion, an der die Lagergehäuse befestigt sind, ausgeglichen werden. Die maximale Betriebstemperatur beträgt 100 °C und die minimale -30 °C.

Ausführung US

Spannlager in der Ausführung US haben einen verlängerten Innenring auf einer Seite. Diese Lager sind für Standardanwendungen auch mit Drehrichtungswechsel geeignet. Der Innenring wird mit zwei Schrauben, die um 120° versetzt angeordnet sind, auf der Welle fixiert. Diese Befestigung gewährleistet eine schnelle, effiziente und einfache Montage des Lagers auf der Welle.

Hauptabmessungen

Kennzeichnung

Käfige

Genauigkeit

Radialspiel

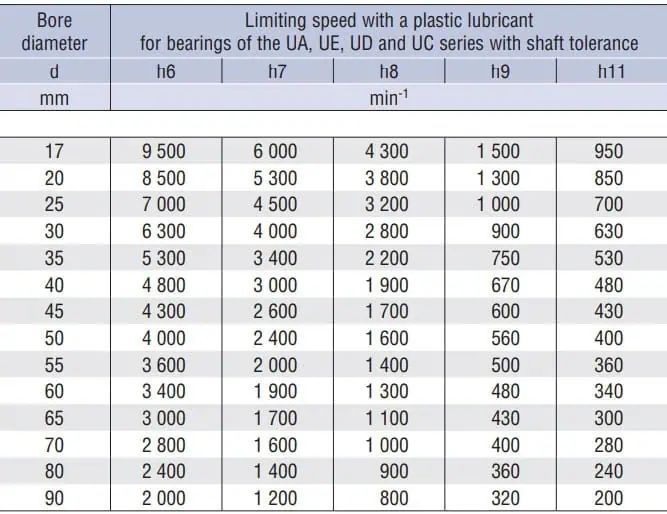

Drehzahlgrenze

Minimale Belastung

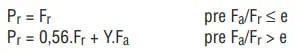

Dynamische und statische äquivalente Lagerbelastung

Die äquivalente dynamische Belastung der Spannlager wird auf die gleiche Weise wie bei Standardkugellagern bestimmt:

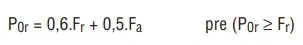

Radialäquivalente statische Belastung

The following applies to the static load of insert bearings:

| Lagerbezeichnung | Abmessungen (mm) | Dynamische Tragzahl | Statische Tragzahl | Gewicht | |||||

|---|---|---|---|---|---|---|---|---|---|

| d | D | C | C1 | s | B1 | kN | kN | kg | |

| US201 | 12 | 40 | 12 | 3.6 | 6 | 22 | 9.6 | 4.6 | 0.10 |

| US202 | 15 | 40 | 12 | 3.6 | 6 | 22 | 9.6 | 4.6 | 0.10 |

| US203 | 17 | 40 | 12 | 3.6 | 6 | 22 | 9.6 | 4.6 | 0.10 |

| US204 | 20 | 47 | 14 | 4 | 7 | 25 | 12.8 | 6.7 | 0.12 |

| US205 | 25 | 52 | 15 | 4.3 | 7.5 | 27 | 14.0 | 7.9 | 0.16 |

| US206 | 30 | 62 | 16 | 5 | 8 | 30 | 19.5 | 11.3 | 0.25 |

| US207 | 35 | 72 | 17 | 5.7 | 8.5 | 32 | 25.7 | 15.2 | 0.36 |

| US208 | 40 | 80 | 18 | 6.2 | 9 | 34 | 32.0 | 17.8 | 0.45 |

| US209 | 45 | 85 | 19 | 6.3 | 10.2 | 41.2 | 32.7 | 20.2 | 0.56 |

| US210 | 50 | 90 | 20 | 6.5 | 10.9 | 43.5 | 35.1 | 23.2 | 0.62 |

| US211 | 55 | 100 | 21 | 7.2 | 11.8 | 45.3 | 43.3 | 29.2 | 1.10 |

| US212 | 60 | 110 | 22 | 8.2 | 14.9 | 53.7 | 47.8 | 32.8 | 1.30 |